Your cart is currently empty.

Deal of the day

Day

Hrs

Min

Sec

-

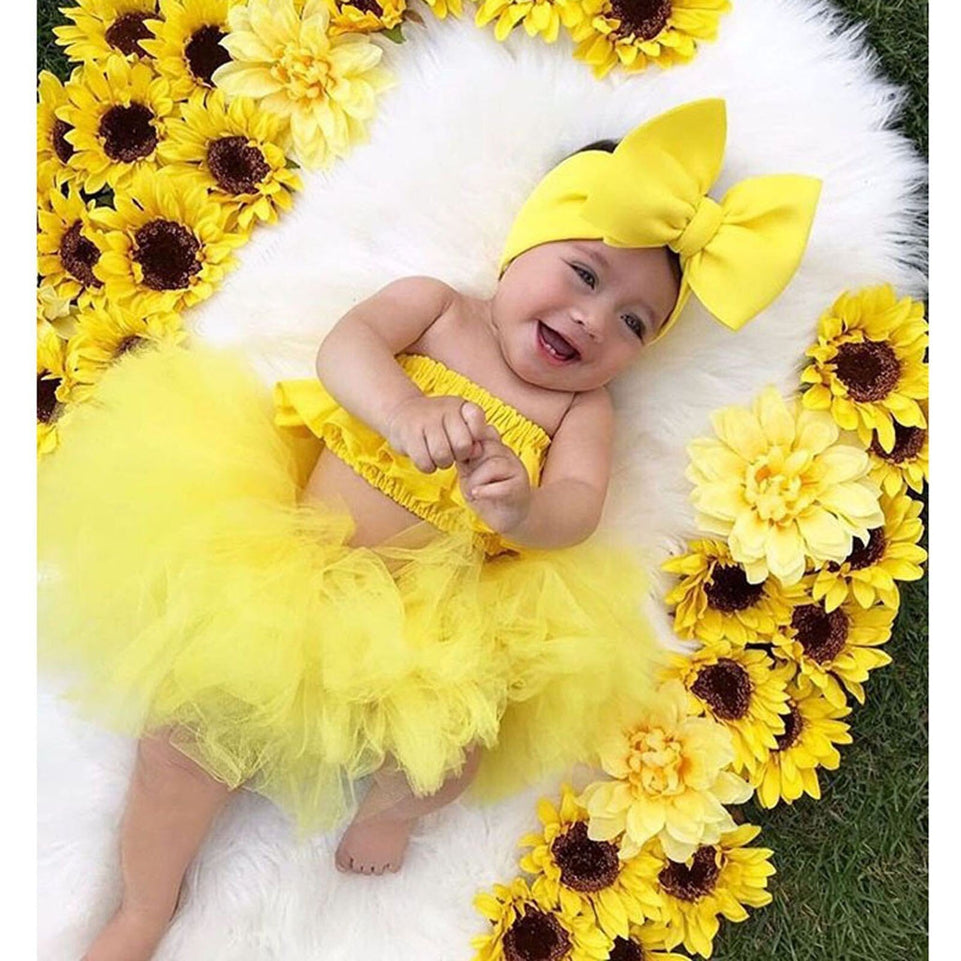

New Summer Baby Girl Dress Big... SPECIFICATIONSBrand Name: NoneOrigin: Mainland ChinaCN: HubeiMaterial: CottonPattern Type: PrintStyle: CasualDecoration: BowSeason: SummerAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mDepartment Name: BabyGender:...

- Regular price

- 3.66 dh

- Regular price

- 3.66 dh

- Sale price

-

- Unit price

- / per

-

IENENS Kids Baby Boy Jumper Girls... SPECIFICATIONSBrand Name: ienensAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mMaterial: CottonOrigin: Mainland ChinaSeason: SummerGender: baby unisexItem Type: RompersDepartment Name: BabyCollar: Turn-down...

- Regular price

- 6.99 dh

- Regular price

- 6.99 dh

- Sale price

-

- Unit price

- / per

-

Boys Grils Clothes Sets Long Sleeve... SPECIFICATIONSBrand Name: FMPDCOuterwear Type: CoatStyle: CasualOrigin: Mainland ChinaCN: ZhejiangMaterial: CottonFabric Type: WorstedSleeve Length(cm): FullFit: Fits true to size, take your...

- Regular price

- 5.36 dh

- Regular price

- 5.36 dh

- Sale price

-

- Unit price

- / per

-

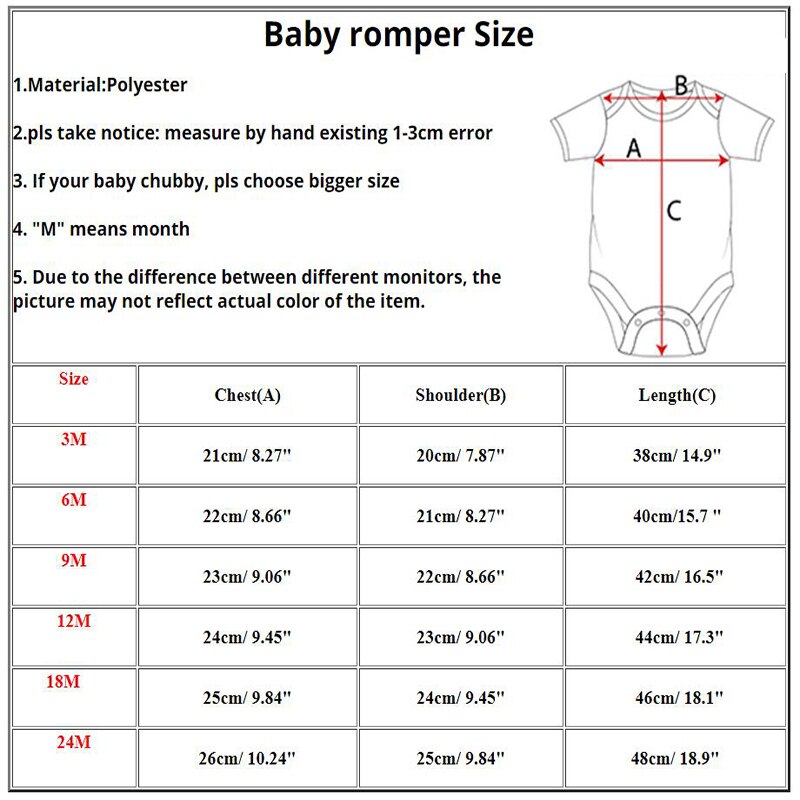

3 6 9 12 24 M... SPECIFICATIONSBrand Name: NoneOuterwear Type: CoatStyle: FashionOrigin: Mainland ChinaMaterial: PolyesterFabric Type: Combed CottonSleeve Length(cm): SleevelessFit: Fits true to size, take your...

- Regular price

- 2.77 dh

- Regular price

- 2.77 dh

- Sale price

-

- Unit price

- / per

-

My Auntie Take Me To The... SPECIFICATIONSBrand Name: MENISCOUNTERStyle: FashionOrigin: Mainland ChinaMaterial: PolyesterGender: baby unisexItem Type: BodysuitsAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mDepartment Name: BabyCollar: O-NeckPattern...

- Regular price

- 4.27 dh

- Regular price

- 4.27 dh

- Sale price

-

- Unit price

- / per

-

Newborn Baby T-shirts For Boys Girls... SPECIFICATIONSBrand Name: LAWADKAMaterial: CottonStyle: CasualOrigin: Mainland ChinaAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mDepartment Name: BabyCollar: O-NeckPattern Type: SolidSleeve Length(cm): ShortFit:...

- Regular price

- 1.74 dh

- Regular price

- 1.74 dh

- Sale price

-

- Unit price

- / per

-

6-36M Newborn Toddler kid Baby Boys... SPECIFICATIONSBrand Name: CANTREEStyle: FashionOrigin: Mainland ChinaMaterial: CottonFabric Type: BroadclothSleeve Length(cm): ShortFit: Fits true to size, take your normal sizeModel Number:...

- Regular price

- 8.37 dh

- Regular price

- 8.37 dh

- Sale price

-

- Unit price

- / per

-

New 0-24M Summer Boys Hollow-Out Rompers... SPECIFICATIONSBrand Name: EmmababyStyle: FashionOrigin: Mainland ChinaMaterial: CottonGender: Baby GirlsItem Type: BodysuitsModel Number: BodysuitsDepartment Name: BabyCollar: O-NeckPattern Type: PrintSleeve Length(cm): SleevelessFit:...

- Regular price

- 1.99 dh

- Regular price

- 1.99 dh

- Sale price

-

- Unit price

- / per

-

New Baby Long Sleeve Romper Cotton... SPECIFICATIONSBrand Name: AllChildAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mMaterial: CottonOrigin: Mainland ChinaCN: ZhejiangSeason: Spring & AutumnGender: baby unisexItem Type: RompersDepartment...

- Regular price

- 12.24 dh

- Regular price

- 12.24 dh

- Sale price

-

- Unit price

- / per

-

MQATZ Summer Dress 1 Year Kids... SPECIFICATIONSBrand Name: MQATZOrigin: Mainland ChinaCN: GuangdongMaterial: CottonMaterial: PolyesterPattern Type: SolidStyle: CuteDecoration: FlowersSeason: SummerActual Images: yesAge Range: 0-6mAge Range: 7-12mAge Range:...

- Regular price

- 31.51 dh

- Regular price

- 31.51 dh

- Sale price

-

- Unit price

- / per

-

Baby Fall Winter Spring Romper Cute... SPECIFICATIONSAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mMaterial: CottonOrigin: Mainland ChinaCN: GuangdongSeason: Spring & AutumnGender: baby unisexItem Type: RompersDepartment Name: BabyCollar:...

- Regular price

- 13.51 dh

- Regular price

- 13.51 dh

- Sale price

-

- Unit price

- / per

-

Newborn Baby Girl Rompers Long Sleeve... SPECIFICATIONSBrand Name: NoneAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mMaterial: CottonOrigin: Mainland ChinaCN: GuangdongSeason: Four SeasonsGender: baby unisexItem Type: RompersDepartment Name:...

- Regular price

- 8.32 dh

- Regular price

- 8.32 dh

- Sale price

-

- Unit price

- / per

NEW PRODUCTS

-

12.5-19cm Fashion Kids Sneakers Boots,Suede Leopard... SPECIFICATIONSBrand Name: ClaladoudouOutsole Material: TPROrigin: Mainland ChinaCN: ZhejiangItem Type: First WalkersAge Range: 7-12mAge Range: 13-24mAge Range: 25-36mFashion Element: TOTEMClosure Type:...

- Regular price

- 16.27 dh

- Regular price

- 16.27 dh

- Sale price

-

- Unit price

- / per

-

Baby Cartoon Shoes for 0-3 Years... SPECIFICATIONSBrand Name: NoneOutsole Material: TPROrigin: Mainland ChinaCN: ZhejiangItem Type: First WalkersAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mAge Range: 25-36mFashion Element:...

- Regular price

- 10.52 dh

- Regular price

- 10.52 dh

- Sale price

-

- Unit price

- / per

-

AOGT 2022 Spring/Autumn Baby Girl Boy... SPECIFICATIONSBrand Name: AOGTOutsole Material: EVAOrigin: Mainland ChinaCN: ZhejiangItem Type: First WalkersAge Range: 7-12mAge Range: 13-24mAge Range: 25-36mAge Range: 4-6yFashion Element:...

- Regular price

- 13.98 dh

- Regular price

- 13.98 dh

- Sale price

-

- Unit price

- / per

-

Baby Toddler Shoes Cute Color Blocking... SPECIFICATIONSBrand Name: NoneOutsole Material: RubberOrigin: Mainland ChinaCN: GuangdongItem Type: First WalkersAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mAge Range: 25-36mFashion Element:...

- Regular price

- 5.22 dh

- Regular price

- 5.22 dh

- Sale price

-

- Unit price

- / per

-

0-5 Years New Baby Shoes Microfiber... SPECIFICATIONSBrand Name: GT-CECDOutsole Material: RubberOrigin: Mainland ChinaCN: ZhejiangItem Type: First WalkersAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mAge Range: 25-36mAge Range:...

- Regular price

- 14.19 dh

- Regular price

- 14.19 dh

- Sale price

-

- Unit price

- / per

-

0-18M Baby Girl Soft Lovely Comfortable... SPECIFICATIONSBrand Name: NoneOutsole Material: CottonOrigin: Mainland ChinaFashion Element: Cross-tiedClosure Type: Lace-upPattern Type: SolidFit: Fits true to size, take your normal...

- Regular price

- 1.39 dh

- Regular price

- 1.39 dh

- Sale price

-

- Unit price

- / per

-

Girls Rome Sandals Summer PU Leather... SPECIFICATIONSBrand Name: NoneUpper Material: Cotton FabricOrigin: Mainland ChinaWhether Plugged: noOutsole Material: CottonShoes Length: 10.5cmShoes Length: 11cmShoes Length: 11.5cmShoes Length: 12cmShoes...

- Regular price

- 2.24 dh

- Regular price

- 2.24 dh

- Sale price

-

- Unit price

- / per

-

Newborn baby boy shoes fashion teddy... SPECIFICATIONSBrand Name: NoneOutsole Material: CottonOrigin: Mainland ChinaCN: ZhejiangItem Type: First WalkersAge Range: MaternityAge Range: 0-6mAge Range: 7-12mFashion Element: ShallowClosure Type:...

- Regular price

- 4.99 dh

- Regular price

- 4.99 dh

- Sale price

-

- Unit price

- / per

-

New Baby Casual Shoes Soft bottom... SPECIFICATIONSBrand Name: For kidsOutsole Material: CottonOrigin: Mainland ChinaCN: ZhejiangItem Type: First WalkersAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mFashion Element: FretworkClosure...

- Regular price

- 3.45 dh

- Regular price

- 3.45 dh

- Sale price

-

- Unit price

- / per

-

Baby sandals kids girls sandals soft... SPECIFICATIONSBrand Name: JOYHOPYUpper Material: LeatherOrigin: Mainland ChinaWhether Plugged: YESOutsole Material: RubberShoes Length: 11.5cmShoes Length: 12cmShoes Length: 12.5cmShoes Length: 13cmShoes Length:...

- Regular price

- 8.45 dh

- Regular price

- 8.45 dh

- Sale price

-

- Unit price

- / per

-

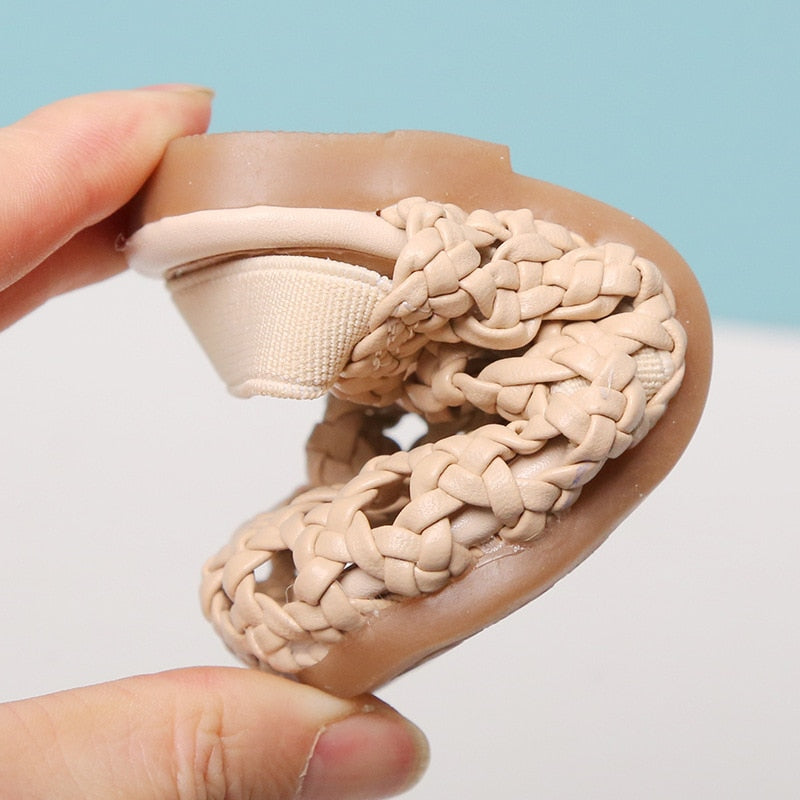

Newborn Baby Weave Shoes Toddler Girls... SPECIFICATIONSBrand Name: NoneOutsole Material: PlasticOrigin: Mainland ChinaItem Type: First WalkersAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mAge Range: 25-36mFashion Element: Cross-tiedClosure...

- Regular price

- 13.79 dh

- Regular price

- 13.79 dh

- Sale price

-

- Unit price

- / per

-

Vintage Baby Shoes 2023 Princess Baby... SPECIFICATIONSBrand Name: NoneOutsole Material: RubberOrigin: Mainland ChinaCN: GuangdongItem Type: First WalkersAge Range: MaternityAge Range: 0-6mAge Range: 7-12mAge Range: 13-24mFashion Element:...

- Regular price

- 2.01 dh

- Regular price

- 2.01 dh

- Sale price

-

- Unit price

- / per